The Essential Supplier Risk Management Guide

Introduction to Supplier Risk Management (SRM)

This Supplier Risk Management guide aims to be the one article you'll need to get started with your SRM program!

If you are a business leader, it is essential to stay up to date on supplier risk management policies and practices. With global markets becoming increasingly interconnected and competition intensifying, companies must be diligent in assessing the potential risks associated with their suppliers as well as crafting robust strategies for mitigating those risks.

This guide will provide insight into:

- What supplier risk management entails

- Why supplier risk management is so important

- Maximizing the effectiveness of your SRM efforts with due diligence process best practices, breach response planning and technology considerations

With this comprehensive overview you will have all the tools necessary to equip your organization for confident risk mitigation decisions today.

Want to dive deeper on SRM at your organization?

Why Supplier Risk Management Is Critical in 2023

As businesses navigate increasingly complex global markets, managing supplier risk has become a critical priority for organizations of all sizes in 2023. Supply chain disruptions in 2020, 2021 and 2022 illustrated the critical importance of solid supplier risk management. The best prepared organizations weathered disruptions arising from COVID and the Ukraine invasion better than others.

Then, just when it seemed like we had all seen the worst, financial upheaval came in 2022 and extended in 2023. Between inflation, the failure of Silicon Valley Bank, and the resulting economic uncertainty, the changing environment further emphasizes the importance of excellent supplier risk management.

A solid supplier risk management program gives visibility into the financial standing and operational capabilities of your suppliers to ensure you receive high quality goods or services on time in normal times, and to ensure you receive them at all in times upheaval.

To help prevent supply chain disruptions, you need a clear understanding of the following factors for all of your suppliers:

- financial stability

- product quality compliance standards

- delivery issues

- resource availability

- operational capabilities

Understanding these factors can help you prevent supply chain disruptions that can have an adverse impact on your business. Risk management is also essential to identify opportunities where new suppliers can provide cost savings or better value for products or services.

This article provides guidance for creating a sustainable risk management program incorporating all of the above factors. To start, we need to define what supplier risk management is.

What is supplier risk management?

Supplier Risk Management is a proactive approach to identifying, assessing, and managing potential risks throughout the organization’s supply chain.

By recognizing problem areas and developing cross-functional strategies to mitigate them, organizations can reduce their risk in relation to suppliers. Furthermore, supplier risk management helps organizations ensure that exposed vulnerabilities do not cause disruption at any point of the procurement process.

How has the economic landscape changed and created more urgent need for SRM?

With the ever-growing global economy and recessionary pressures, companies are facing more unpredictability in their supply chain operations. As markets grow more volatile, there is a greater need to have better visibility into supplier performance. Supplier Risk Management has become increasingly vital for companies and organizations to ensure that their supply chains stay reliable and safe – whether it’s from increased costs, reduced quality or company reputation damage.

An active supplier risk management program is just one part of an overall supplier relationship management strategy that will allow your organizations to proactively manage the supply risks that might infringe upon an organization’s ability to ensure effective delivery.

Additionally, implementing a successful risk management strategy helps companies prepare for sudden shifts in the economic landscape and rapid fluctuations in regulations within different countries or regions. The long-term benefits of supplier risk management extend far beyond ensuring smooth supply chain operations – risk management is also key in helping businesses remain competitive in today's global environment.

The growing importance of supplier risk management in a globalized economy

The globalization of the economy has dramatically increased opportunities for businesses of all sizes, but in turn this has created a far more complicated environment to navigate. Supply chain risk management (SCRM) has never been more important than it is today — it is essential for companies to understand their suppliers and the impacts these have on operations, profitability, and customer experience.

Companies must have complete visibility of each element in their supply chain network and an understanding of how suppliers’ processes affect their ability to deliver products or services with integrity. This ensures that safety and quality standards are met, minimizing risks associated with reputational damage due to non-compliance or delays in deliveries. SRM also provides the company with actionable intelligence that enables them to make swift decisions before potential risks cause disruption further down the line.

Advantages of incorporating supplier risk management into your company

Supplier Risk Management is an important tool for businesses to identify and mitigate risks associated with their suppliers. Implementing SRM into your company could provide a range of advantages, such as:

- improved visibility into the supply chain

- access to new methods of risk monitoring

- enhanced stakeholder confidence in the organisation

SRM can also help to develop a stronger relationship between your organisation and its suppliers by ensuring regulatory compliance and building trust. By successfully incorporating SRM into your company, you will be well on the way to achieving maximum value from your investment in supplier partnerships.

The potential cost savings from effective SRM programs

The potential cost savings from effective supplier risk management (SRM) programs are far-reaching and can result in cost reductions across the supply chain. Companies that successfully implement SRM can benefit from reduced operations costs, improved productivity, decreased risks, and streamlined procedures which all result in financial rewards across the board.

In addition, when risks are prevented or mitigated upfront due to proactive SRM practices, overall budgets may also experience a reduction. It's cheaper to avoid a loss event than to recover from one. This proactive approach lowers overhead costs and expenses in the long run. As such, companies should consider potential investments into SRM initiatives as methods to reduce short-term spending while reaping long-term financial benefits.

Types and Examples of Supplier Risks

Supplier risks come in many different forms and can emerge from a variety of sources. When left unmitigated they threaten corporate performance and reputation. This section of our Supplier Risk Management Guide describes the most common supplier risks.

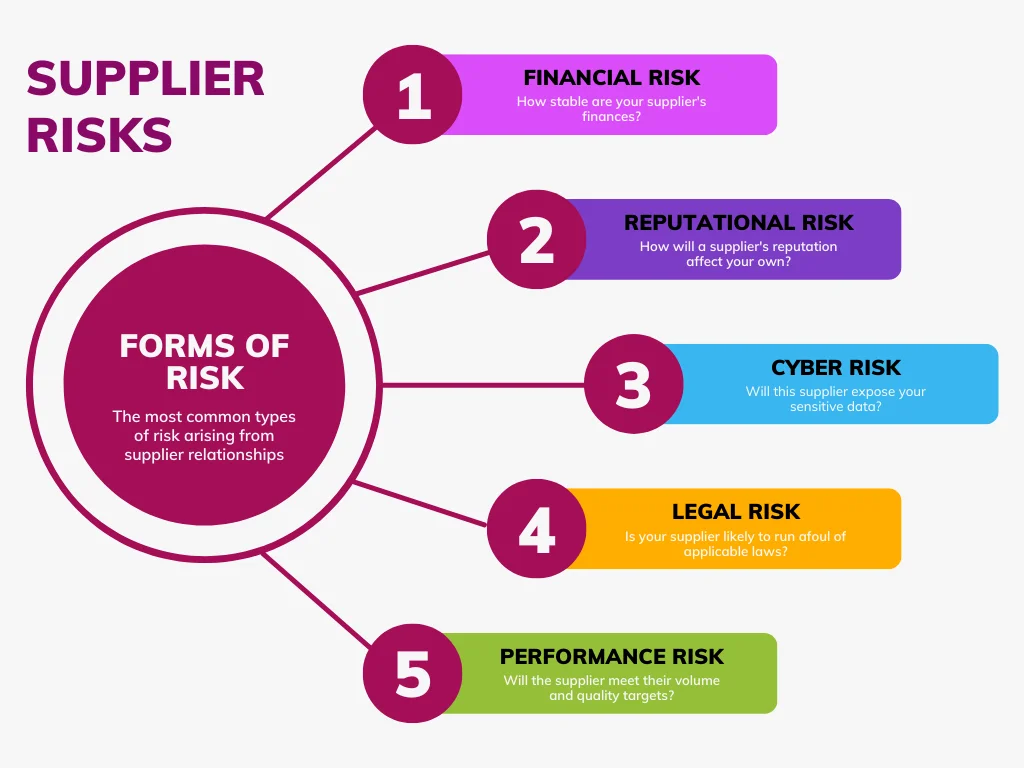

What are some common types of supplier risks?

Supplier risk management involves being aware of all the risks posed by companies and organizations that you depend on to provide goods, services or resources for your own organization.

The major categories of supplier risk include:

- financial risk

- reputational risk

- security & data protection risk (cyber risk)

- compliance & legal risks

- service delivery & performance risk

Financial Risk

Financial risk relates to the stability of suppliers' finances - whether they could be at risk of bankruptcy or their capacity to meet delivery commitments.

Reputational Risk

Reputational risk looks at how a supplier's reputation affects yours and how it is perceived in the industry or marketplace.

Security & Data Protection Risk (Cyber Risk)

Security & data protection or cyber risk is an important measure to ensure your data remains secure with third-party suppliers.

Compliance & Legal Risk

Compliance & legal risks involve ensuring that all partners comply with local laws as well as organizational policies and procedures.

Service Delivery & Performance Risk

Service delivery & performance risks relate to the likelihood of the supplier underperforming their target volumes or product quality, and the potential impact on your business.

It is important for organizations to effectively manage these common types of supplier risks in order to ensure their continued success and stability.

Examples of cyber security risks from suppliers

Suppliers of products and services can present a wide range of cyber security risks to organizations. For example, without the appropriate data security measures in place, suppliers with access to sensitive information can potentially lead to unauthorized disclosure, leaving businesses susceptible to data breaches which impact customer trust and reputation. Additionally, suppliers may have inadequate protection from malicious attacks such as viruses and Trojans that can impact the integrity of systems and operations. Therefore, when choosing a supplier, organizations should analyze their risk profile carefully to identify vulnerabilities in their system that could have an adverse effect on overall business operations. Risk mitigation activities such as developing vendor relationships and managing contracts should be considered for any supplier that presents a potential risk.

Examples of environmental or safety risks from suppliers

Suppliers are an integral part of the supply chain and their operational activities carry a wide range of environmental and safety risks. The safety hazards posed by a particular supplier can arise from the quality of the materials they use, any operations they undertake or even in potentially hazardous workplaces. Even seemingly minor risks can have major consequences if not managed properly. It is important for companies to put risk management strategies in place that take into account both short-term and long-term consequences of any potential hazard associated with their suppliers. Examples of such risks include damage to tangible resources as a result of faulty or restricted maintenance protocols or illegal dumping hazards caused by inadequate waste management practices. The long-term effects of these activities must be carefully monitored and managed to ensure compliance with applicable laws, providing assurance that all stakeholders are provided with a safe working environment while also preserving the environment.

How noncompliance with regulations creates legal risk

Companies are responsible for ensuring they comply with all applicable regulations that govern their organization’s operations. Noncompliance with regulations can create a legal risk and leave companies exposed to regulatory action, fines, or lawsuits. Companies need to maintain an understanding of the ongoing changes in the regulatory landscape, ensure their internal processes remain compliant and consistently monitor suppliers to mitigate any potential legal risks resulting from noncompliance. Implementing a robust supplier risk management strategy is key to helping organizations maintain compliance with regulations as well as promote ethical practices among its suppliers.

Other important supplier risks to consider

Reviewing other important supplier risks should also not be overlooked when drafting your supplier risk management guide. These may include financial stability and related solvency, intellectual property rights protection, privacy, reputation protection and security/privacy of data managed by suppliers as well as environmental factors such as a company's adherence to the necessary sustainability standards. Assessing the exposures associated with all of these external supplier risks is critical to ensure the continued success of your business. By implementing best practices and leveraging technology to capture relevant data points on customer profiles, companies can quickly gain insight into each supplier’s total risk profile to make informed decisions about which suppliers or vendor partners should be relied on for strategic projects.

Which SRM activities are you struggling to execute?

All the work that goes into effective SRM can seem overwhelming. To learn about Vendorful’s how Supplier Relationship Management software makes it easy, click to set up a call with one of our experts.

Industry-Specific Supplier Risk Management Concerns

No two industries have the exact same risk factors when it comes to supplier management. Industries such as manufacturing, medical equipment, pharmaceuticals, automotive, and aerospace requiresuppliers who meet special requirements. For these companies, failure to find qualified suppliers can mean huge losses of product, time and money. This is why many organizations have taken steps to establish industry-specific supplier risk management processes that consider unique risks associated with the industry in question. From safety protocols and adherence to regulations, to participation in quality and environmental initiatives, managing risk factors specific to an industry requires due diligence on both sides and clear communication between buyers and sellers. An effective supplier risk management program tailored not just to a company’s processes but also their industry will go a long way toward ensuring successful business relationships.

Understanding differences across industries when it comes to supplier risk

Supplier risk management is a critical component to any successful business, particularly when it comes to working with large and complex vendors. However, there are often small but vital variances in the supplier risk management process across industries, making it essential to have an understanding of them. In the healthcare sector, for example, the potential for medical negligence poses a serious threat to patients and staff alike—so thorough screening processes for suppliers must be implemented. Additionally, legal or compliance issues may mean extra background checks or process audits should be conducted with suppliers from sectors like financial services. Conversely, certain environmental regulations might not apply to certain industrial sectors as much as others—but it's always important to remain aware of any laws surrounding supplier risk management that could impact your business. A comprehensive guide on supplier risk management can provide invaluable guidance on how best to approach these tasks in different industries.

Common challenges faced by different sectors, such as health care or finance, when managing their supply chain risks

Managing supply chain risks is an incredibly important task for various industries, especially those in health care and finance. These sectors face many difficulties when trying to keep their operations safe, secure, compliant and profitable - all of which can be affected by the suppliers with whom they exchange goods and services. Companies must understand the legal requirements surrounding these relationships and stay aware of any emerging risks that can put their businesses at risk. Furthermore, not every sector has access to the same resources available for managing supplier risk; this in itself creates further obstacles for healthcare and finance to overcome as they strive to maintain strong supply chains. With comprehensive understanding and dedicated time devoted to thoroughly assessing suppliers’ background information, policies and procedures, healthcare organizations and financial institutions can deftly maneuver the complex challenge of supplier risk management.

Defining actionable strategies specific to different industry needs when addressing their unique supplier risk concerns

When it comes to addressing unique supplier risk concerns, it is imperative that different industries develop actionable strategies that are tailored to their individual needs. To ensure success in this area, it is important for those within the industry to first understand the supplier risk landscape within their sector and any regulations or guidelines currently in place. Having a clear understanding of what constitutes a viable and actionable strategy will help tremendously when tackling different industry-specific concerns. Additionally, leveraging technologies like blockchain or artificial intelligence can be valuable resources when creating strategies related to supplier risk management. Accessing real-time data and harnessing advanced analytics helps businesses stay ahead of trends and provide added protection from potential risks. Throughout this guide, we will discuss in greater detail how different industries can create effective strategies for managing supplier risk.

Understanding Profiled Risk, Inherent Risk & Residual Risk in the Supply Chain

Understanding the risks associated with supplier collaboration is essential to any successful supply chain. Profiled risk, inherent risk, and residual risk are three distinct categories of risk that can have a huge impact on a company's bottom line. Profiled risk is the level of risk posed by the supplier at the time of introduction into the organization’s supply chain. Inherent risk corresponds to the amount of risk transferred to and accepted by a partner or vendor when they enter into a business relationship; this category takes into consideration both initial and residual exposures over time. Residual risk represents whatever risks remain after mitigating profiled and inherent risks, as well as any surprises or unforeseen circumstances that arise along the way. Knowing how to recognize these risks can help protect companies from unanticipated losses in their commercial relationships and ensure greater success overall.

Defining profiled, inherent and residual risk categories within the supply chain

Working within the supply chain means understanding how to manage risk effectively in order to minimize disruption and loss. A key part of this is being able to distinguish between different types of risk and knowing how they apply to supplier risk management. In this case, it is essential to understand the differences inherent in profiled, inherent and residual risk categories. Profiled risks are identified as a result of an organization's own internal processes and are generally easier to detect or implement controls for because decision-makers have better knowledge of them. Inherent risk, on the other hand, can be both external and internal factors that may lead to financial loss or a similar adverse event, such as design flaws or warranty issues. Lastly, residual risks refer to remaining sources of risk even after controls have been implemented; these typically involve more investment or resources but may ultimately increase the overall security of the supply chain. By understanding these definitions, companies can build a comprehensive approach to managing its supplier risks.

How Profiled Risk, Inherent Risk and Residual Risk interact with each other

A comprehensive supplier risk management program demands a close look at profiled risk, inherent risk and residual risk, since these three risks interact with each other in powerful and far-reaching ways. Depending on the volatility of their supply chain landscape, organizations may find they are more prone to certain types of risks. The interplay between these three components can grant businesses an invaluable perspective into potential loss drivers and allow them to understand the significance of effective supplier risk identification and assessment protocols - all of which should be included in a robust supplier risk management plan. With better insight into how profiled risk, inherent risk and residual risk can come together to create a significant liability for business owners, organizations will be able to develop customized processes for meeting their individual needs more effectively.

Identifying which type of risk you should prioritize first

Identifying which type of risk to prioritize first is a crucial step when establishing effective supplier risk management. Many businesses face multiple issues and threats from their supply chain which can become overwhelming without proper organization and analysis. Analyzing the risks according to their potential financial, regulatory, reputational, or operational impact on the organization will give you a clear idea of what needs the most attention. This approach requires an internal assessment of the potential losses associated with different types of risk and then weighing them against existing resources. Risk mitigation strategies should be tailored to ensure they are appropriate for each particular risk, but prioritizing those which pose the greatest threat is key.

A Supplier Risk Management Strategy Outline

A Supplier Risk Management Strategy is essential for any business looking to reduce risks and optimize their processes. It provides an outline of the actions needed to identify, assess, monitor and control the risks associated with each vendor that the company works with. This strategy should cover areas such as supplier performance standards, strategies for compliance with established standards, risk management protocols, and desired outcomes for supplier relationships. A comprehensive Supplier Risk Management Strategy should be detailed, but still be flexible enough to accommodate changes in market conditions. This long-form guide will assist businesses in establishing a well-defined set of policies that promote transparency and accountability within relationships with vendors while minimizing future threats before they arise.

Establishing an overarching framework for your SRM strategy

Establishing an overarching framework for your supplier risk management (SRM) strategy is essential for understanding the risks associated with any given supplier and taking the necessary steps to manage them. It involves setting clear objectives, policies, processes and procedures in place to ensure that risk is systematically assessed and monitored across all aspects of supply chain operations. A framework also helps to identify which roles are responsible for ensuring compliance with SRM standards, what controls should be evaluated on a regular basis, and how operational data should be collected and analyzed in order to improve supply chain performance. With an encompassing framework in place, organizations can continually review their SRM strategies to ensure they are up to date and relevant while also addressing risks before they present themselves as potential issues.

Creating a plan for monitoring existing suppliers and onboarding new ones

A proper monitoring plan for suppliers is an essential part of a successful risk management system. In order to create such a plan, it is important to understand that it should focus on both existing supplier relationships and new ones. When forming your plan, you will need to consider factors such as maintaining standardized processes; conducting regular performance reviews; implementing automated checks and controls; improving data accuracy and consistency; using consistent monitoring metrics; and revisiting the onboarding process for new suppliers. It is necessary to ensure that the entire process runs smoothly and efficiently in order to get the best results from dealing with suppliers in terms of risk management. By taking the time to develop a strong monitoring plan, you can rest assured that your supplier relationships will be managed well in the long-term.

Developing quality assurance procedures such as onsite reviews

Supplier risk management requires comprehensive quality assurance procedures to ensure that suppliers are meeting the standards of quality set by businesses. Developing these procedures can be complex and should involve an in-depth review of a supplier's capabilities and aptitude to deliver. One key component of this assessment/review process is onsite reviews. This involves a designated employee or an external auditor going to the supplier site to understand their operations, processes, skill levels, and any other relevant considerations. Onsite reviews provide business owners with valuable insight into the supplier’s internal operations, personnel capabilities, equipment status, and compliance with said quality standards.

Implementing databases or software systems to manage your network of suppliers

The implementation of databases or software systems to manage your network of suppliers is a highly effective and efficient method for tracking, assessing, and ultimately minimizing supplier risk. These systems allow organizations to automate certain processes and responsibilities related to identifying, evaluating and monitoring the performance of their suppliers how they function. The results are improved operational visibility into supplier intelligence; improved data accuracy; scalability for operations if the number of companies in the portfolio increases; increased efficiency by automating manual processes allowing for employees more time to be spent on other activities. Organizations can make more informed decisions about which suppliers are best equipped to work with them as well as get a better understanding of any potential issues that may arise with each supplier. As such, implementing databases or software systems to manage your network of suppliers is key in staying up-to-date on supplier risk management and performance!

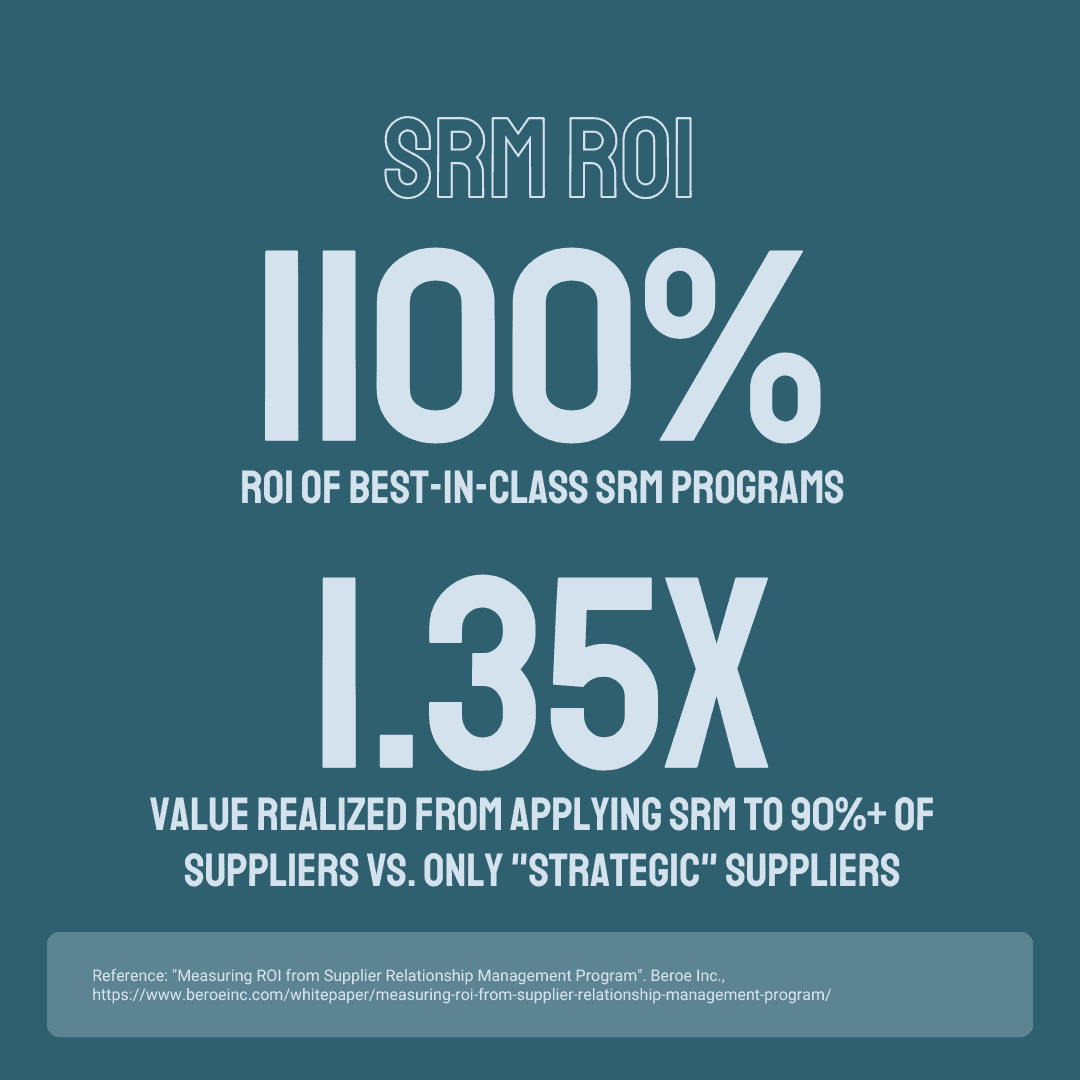

The ROI of SRM

What kind of ROI will your organization achieve with better SRM?

The right solution makes it easy to apply best practices and achieve better outcomes and ROI. To learn about Vendorful’s how Supplier Relationship Management software can help you achieve your goals, click to set up a call with one of our experts.

Supplier Risk Management Best Practices and Tips for Your SRM Program

Every successful Supplier Risk Management (SRM) Program requires a comprehensive plan. If you want to be successful in managing the risks inherent in doing business with suppliers, there are some tips to keep in mind. First and foremost, it is essential to build an understanding of supplier risk management processes with your entire organization. Having leadership, managers, and all personnel on board with SRM initiatives will ensure that risks are identified and addressed throughout the organization. It is important to also develop evaluation criteria for potential suppliers before initiating sourcing activities - this provides an efficient framework for comparison and allows your organization to objectively select vendors based on their ability to address any risks posed. Additionally, make sure that your program includes ongoing monitoring of partners - changes can occur quickly and it is vital to be aware of them on a regular basis in order to take action if needed. Finally, consider developing proactive engagement strategies such as customer feedback programs or operation performance reviews for existing and potential suppliers - this can provide valuable insight into ways in which risks may be further mitigated or prevented from arising in the first place. By following these tips as you develop your SRM program, you can help ensure optimal protection against supplier-related risks for your business.

Introducing employee training on best practices for managing suppliers

Training employees on supplier risk management is a critical practice for organizations looking to maintain safe, secure, and reliable operations. By equipping staff with the best-in-class understanding of how to manage their suppliers, companies can achieve higher standards of efficiency, reduce the possibility of fraud and misconduct, and maximize the quality of their services. Through employee training focused on supplier risk management best practices, businesses can gain an improved competitive advantage in today's ever-changing business environment. Additionally, these training programs give employees the opportunity to interact in ongoing evaluations–contributing to a proactive approach towards controlling risks associated with workplace safety and security. With consistent employee training paired with expert guidance from leadership teams, organizations can create a strong built-to-last foundation for supplier risk management.

Designating staff members as point people responsible for ongoing vendor interactions

Designating staff members as point people for ongoing vendor interactions is an important part of successful supplier risk management. Without having one point person for each relationship, tasks can easily get lost in the shuffle or neglected completely. With a designated contact from both sides of the partnership, clear lines of communication are established and expectations are better understood. Having a dedicated contact also gives vendors a direct go-to which encourages the development of stronger relationships between partners. This ultimately leads to smoother operations and better results in all areas related to supplier risk management.

Setting up regular check ins/audits with your vendors to monitor performance metrics

Maintaining an effective system of checks and audits with your suppliers is a crucial component of risk management. Regular check ins can help identify problems or issues in a timely manner, allowing you to adjust your strategy accordingly. With regular check-ins or audits, key performance metrics become easier to track and monitor for improvement. Establishing structured rules for both internal as well as external teams can streamline the process and ensure reliable, consistent results. Adopting such a system can offer numerous benefits, by providing reassurance that your suppliers are meeting the standards you have set out. Additionally, it also allows you to use data points to discern trends in supplier performance which may guide more effective decisions going forward.

Leveraging analytics tools or predictive models to anticipate potential supply chain disruptions

Predictive modelling can help organizations to gain a better understanding of supply chain disruptions and proactively mitigate supply chain risk. Leveraging analytics tools gives organizations the power to anticipate potential disruptions that may arise from certain fluctuations in the market or environment. By using predictive analytics, organizations can identify risk factors ahead of time, enabling them to make informed decisions about potential measures that should be taken in order to prevent any major supply chain interruptions. This can save organizations significant amounts of money and resources in both the short and long term, ensuring consistent business continuity.

Ultimately, a successful and comprehensive supplier risk management system hinges on ensuring all steps are taken with consistency and monitoring. Organizations should make sure they understand the risk profile of their suppliers and build strong relationships with them. Employing proactive strategies can also help reduce risks such as engaging reputable audit firms and establishing continuous communication processes to ensure compliance. Additionally, it is important for organizations to remember that risk management does not just stop at reviewing current suppliers — but also involves keeping up-to-date on changing industry regulations and emerging supplier trends. By developing a hefty risk prevention strategy and putting it into practice, organizations can take the proper steps to protect their assets from money-draining supplier disasters while protecting brand reputation and customer satisfaction—guiding businesses to greater resilience in this ever-changing arena.

Interested in learning more beyond this Supplier Risk Management guide? Check out this article on the Vendor Risk Management Lifecycle.

Learn More about Vendorful

The right solution makes it easy to apply best practices and achieve better outcomes and ROI. To learn about Vendorful’s Supplier Relationship Management software and address the pitfalls of your purchasing process, click to set up a call with one of our experts.

Want to see a Demo?

Learn how Vendorful can kickstart your SRM program!